A small leak appeared between the gearbox and the engine. Oil leaks between the engine and gearbox: diagnostics and repair methods. Oil is leaking from the engine or gearbox: main causes and repairs

An oil leak between the engine and gearbox may indicate a serious malfunction. This phenomenon is unacceptable to ensure the normal operation of the units, and every driver strives to get rid of this problem as quickly as possible. However, it is not always possible to quickly and easily detect the causes of a malfunction.

Technical features of engine and gearbox lubrication systems

The design features of the engine and gearbox and their operating conditions determined the use of specific lubricants for each of these units. For technical reasons, it is impossible to fill the engine and gearbox with the same oil. For each unit, the use of liquids of different chemical compositions is provided.

The rubbing parts of internal combustion engines are lubricated thanks to a forced oil supply system to the right places. In gearboxes, mechanically contacting parts are enveloped in transmission fluid. This happens through self-spraying of oil by rotating parts.

The fluids used for the engine and gearbox differ in their chemical composition, viscosity level, additives used, and other technical characteristics. Various deadlines for replacing substances in these units have also been established. Engine oil is changed on average every 10,000–15,000 km. The transmission fluid of the gearbox retains the necessary performance much longer: it is changed after 60,000–90,000 km. Some manufacturers indicate that changing the oil in the gearbox is not provided until the end of the life of this unit.

Another important technological point should be taken into account. It is determined by what oils are used. It can be mineral water, semi-synthetic, synthetic. The service life and retention of astringent elasticity of such oils are not the same. In other words, each of them runs in its own way.

Therefore, situations are quite predictable when, when using mineral water, there was no oil leak between the engine and the gearbox, but after switching to another type of oil, it appeared. Practicing repairmen and experienced car enthusiasts tend to attribute such cases to different oil viscosities. Semi-synthetic and synthetic fluids have better fluidity compared to mineral water.

What causes a leak?

Practice shows that an oil leak at the junction of the engine and gearbox is a consequence of a malfunction of one of these units. Rarely, but there are still cases when leakage channels appear simultaneously in both nodes. A clear sign that lubricant is leaking out is oil stains under the front of the underbody of the car.

The first clue to determining where the oil is coming from is checking the lubricant level in the engine crankcase. If the dipstick shows a sharp drop in the oil level in the engine, then we can assume that the cause of the leak lies in engine malfunctions. The amount of lubricant lost will be indicated by the size of the oil stain.

The next step is to try to determine the quality of the leaking liquid. Engine and transmission oils differ in smell and consistency. The composition (degree of viscosity) and the aroma emitted will tell you what kind of fluid - engine or transmission - the car is losing. There is a simple way to determine. You need to place a piece of leaked lubricant in a container filled with water. The motor oil will curl into a drop and sink to the bottom. And a particle of transmission fluid will spread across the surface.

An accurate determination of the causes of lubricant leakage is hampered by limited access to inspect the areas between the engine and gearbox. Then you can take advantage of the results of operational practice and the advice of experienced drivers. Among the reasons that lead to oil leakage between the engine and gearbox are:

If the signs are accurately identified, the possible causes of leaks can be analyzed in detail. Then it is much easier to eliminate defects or causes of malfunctions. It is risky to take any action to eliminate an oil leak without determining where it is leaking from.

Engine malfunction

Often the cause of oil leakage is a leak in the rear oil seal on the engine crankshaft. Such risks especially increase in cars with high mileage. The oil seal may be squeezed out due to worn crankshaft thrust rings. Rough oil-resistant rubber edges will not stop hot oil. It will definitely break out.

The appearance of a leak is the result of the accumulation of an increased amount of gases in the engine crankcase. This situation is very likely due to wear of the cylinder-piston group and contamination of the gas exhaust system. The ventilation ducts of worn engines and gearboxes are extremely dirty. The pressure in the crankcase increases, and the cuffs, gaskets or seals cannot withstand the lubricant rushing out. Leaks make themselves known by copious dripping of oil and can result in a major engine overhaul or flushing of the crankcase gas exhaust system.

Crankcase ventilation is checked through the condition of the oil deflector valve. It is installed in the valve cover. A bluish or dark brown coating on the valve indicates problems with crankcase ventilation. To final check the functionality of the system, perform the following operation:

- remove the oil filler cap;

- cover the neck with thick cardboard;

- start the engine;

- bring the crankshaft speed to 1000 rpm.

The operation of the ventilation system is considered normal if the cardboard is tightly pulled to the neck due to the vacuum formed in the crankcase. Otherwise, the connecting rubber tubes are cleaned of internal carbon deposits. If this does not help, then the tubes must be replaced.

Oil leaks through the rear oil seal located on the engine crankshaft not only contribute to a noticeable decrease in the fluid level in the sump. Loss of lubricant through this channel often leads to it ending up on the clutch parts. This causes it to slip and prevents further normal movement of the car.

Prolonged downtime of a car (over 4 weeks) results in a lubricant leak. When the engine does not start for more than a month, the oil drops into the crankcase. The seals remain without lubrication, dry out and collapse or become deformed.

The corresponding indicator located on the instrument panel will indicate insufficient oil pressure in the engine. In case of such an alarm signal, the operation of the vehicle must be suspended.

Oil leaks caused by problems with the gearbox

Lubricant leakage occurs not only from under engine parts, but also from the gearbox. In cars equipped with manual transmissions, transmission fluid rarely leaks out. In such gearboxes, the lubricant level is lower than the input shaft bearing.

It is much more common for transmission fluid to leak from automatic transmissions. In such units, the lubricant is supplied to the rubbing parts by force. An oil pump is used for this. As a result, the internal pressure in the lubrication system of the automatic transmission increases.

The main culprit in the problem of oil leakage from the automatic transmission is the torque converter. In many situations, it goes out of service at the same time as the pump. Forced replacement of the listed parts entails significant financial costs. Moreover, repairs sometimes turn out to be ineffective. Then it is easier to purchase a new automatic transmission than to repair the old one.

Eliminating oil leaks from the engine and gearbox

Some reasons leading to loss of transmission fluid from the gearbox can be eliminated without dismantling this unit. The following can be easily corrected:

A leak through the oil pressure sensor will require immediate replacement of the device. There is a rubber diaphragm inside the part. Its wear or loss of integrity causes a malfunction. The diaphragm may rupture. Then the engine lubricant is expelled through the sensor within a few minutes.

Some signs associated with a transmission fluid leak indicate that the transmission may need to be removed. This operation may be necessary if:

When eliminating the above reasons does not stop the flow of lubricant, you need to prepare for serious repair work. They can be expensive. Therefore, it is recommended to make at least a rough estimate. This procedure will help determine which option is more acceptable: serious repair of the box or its complete replacement.

Transmission fluid foams in the gearbox

During normal operation of the engine and gearbox, there are cases when the lubricant foams. Such a defect does not create direct and tangible problems. But foaming transmission fluid creates feelings of discomfort and anxiety in car owners.

Transmission oil foams for 2 main reasons:

- incorrect transmission fluid level;

- technological inconsistencies in the production characteristics of the oil.

A low or high level of lubricant in the gearbox is the most common reason that the substance foams. If the marks on the dipstick reveal an overflow of liquid, then you must immediately remove the excess amount. German cars of the brands Audi, BMW, Mercedes, Volkswagen are the most vulnerable to problems with excess oil in automatic transmissions.

A low level of transmission fluid is usually caused by a leak due to an unsuitable gasket. Over time, this part loses elasticity and does not cover the entire protective perimeter. A leak forms somewhere. The problem is resolved by replacing the gasket.

It is strictly forbidden to add new oil to the automatic transmission, which is not the same as the old one according to the manufacturer. When lubricants from different manufacturers are mixed, the formation of foaming oil is guaranteed. When switching to using a fluid from another company, you need to thoroughly rinse the automatic transmission to remove any remnants of the old substance. And then completely change the oil in the automatic transmission.

Do oils and additives eliminate noise in the gearbox?

Practice proves that noise in the operation of the gearbox appears as the car moves, both at speed and in neutral gear. In this case, the nature of the noise will be fundamentally different. But in any case, the presence of noise indicates a malfunction of the gearbox, which can lead to lubricant leakage.

A hum in the gearbox while driving in neutral is associated with damage to the drive shaft bearing or a low level of transmission fluid. The failure of the synchronizer clutch or blocking component is indicated by noise that appears while driving in a certain gear. This often happens at speed 3 and above. Extraneous noise is caused by a loose gearbox. Incomplete pressing of the clutch pedal also provokes the appearance of noise or grinding noise in the gearbox. These problems lead to lubricating fluid running between the engine and gearbox.

Added additives, which contain special substances to restore the elasticity of seals, help prevent oil leaks for a short time and eliminate noise. This ensures the restoration of tight contacts between the oil seals and shafts. If the oil leaks insignificantly, it may stop for a while. However, the wear of parts is not preserved, and serious damage is not repaired.

Additives can have a negative effect on vehicle components. High-quality oils initially contain additives in balanced proportions. Adding new components violates the established relationships. The transmission fluid will lose some of its functional properties. But that's not so bad. Adding an additive leads to clogging of the engine or gearbox lubrication systems. Therefore, it is better to abandon dubious experiments and use exclusively transmission fluid that is recommended by the car manufacturer. And you will have to refrain from using additives in order to avoid serious technical consequences.

Experienced technicians and car owners do not recommend using oil thickeners. These substances can stop flowing. But at the same time, lubrication of mechanical components deteriorates and wear on engine or gearbox parts increases. In extreme cases, the use of a softening sealant is allowed.

Fixing an oil leak should not be delayed. A drop in the lubricant level in the engine or gearbox leads to serious damage to these units. The released lubricant contaminates other functionally important parts and components.

Have you ever found traces of leaks in the engine compartment or noticed oil stains under your car? The appearance of such factors indicates serious malfunctions in the vehicle, which should not be ignored. Let's talk about why oil leaks occur between the engine and gearbox, and how to fix this problem.

-

Peculiarities

Lubricants poured into the engine compartment and transmission of a car, first of all, must provide structural parts with a reliable degree of protection from premature wear. But due to the fact that the operating conditions of these systems differ significantly, it is impossible to use a liquid with the same viscosity and chemical composition in both cases.

Both lubricants - transmission and motor - are classified according to the international SAE system and can have mineral, semi-synthetic and synthetic bases. This is probably where their similarities end.

The vehicle's engine system operates under conditions of high temperature and operational overloads. That is why it requires a liquid that is resistant to climatic changes and prevents the formation of oxidative reactions inside the working area. In addition, it should wash out carbon particles formed during the operation of the car from the engine compartment, making it easier for the parts to “freely move.” Motor fluid circulates inside the system under high pressure, so its viscosity should not be excessively high.

As for gearbox oil, excessive fluidity cannot occur here. It is supplied to parts by spraying, is not subjected to critical overloads and does not require a large amount of additives.

Such differences in the use of lubricants determine their useful life in a vehicle: for motor fluid it varies between 5-10 thousand kilometers, for transmission fluid - 60-80.

Looking for reasons

Viscosity of motor oils at a temperature of – 20 degrees

Oil leakage from a car engine or gearbox may begin immediately after it is replaced. The presence of smudges may indicate that the fresh fluid does not meet the requirements stated by the car manufacturer. For example, instead of the usual thick mineral water, you decided to use liquid synthetics. If the car refuses to accept it, you will know about it immediately. This problem can be easily resolved - just fill the engine or transmission with oil with the required viscosity.

If the lubricants used have the required parameters, and smudges are still visible on the engine or gearbox, then the situation may be serious. Failure of one, even the smallest component, can disrupt the tightness of the systems and cause oil starvation. This is why it is so important to fix the leak in a timely manner.

The first step is to figure out which system the oil has leaked from.

Primary diagnosis begins with studying the consistency, smell and color of the leaked liquid. Gearbox fuels and lubricants have a dark, sometimes reddish tint and a very pungent odor. The liquid is thick and does not absorb contaminants. Those. a drop of transmission oil will be covered with a layer of dust, but will not absorb it.

As for motor lubricant, it will behave differently towards contaminants: it completely absorbs them. Fuel and lubricants for internal combustion engines have a more liquid base, a reddish-amber tint and a faint odor.

If visual inspection of smudges is difficult due to the design features of the car, then the problem can be solved using an oil dipstick. Measure the fluid level in the engine compartment; deviation of this indicator from the norm will indicate a problem.

Some modern cars have a dipstick to check the oil level in the box. But it will only identify the problem if the lubricant is rapidly leaking out of the gearbox. In these cases, dark stains of technical fluid can be recognized under the front of the car. Minor leaks at the lubricant level will not be immediately noticeable; the dipstick will not be able to “notice” them.

Grease leaks from the engine

If an inspection of the car and a study of the condition of the leaking fluid gave reason to believe that the problem lies in the engine compartment, then it is necessary to identify the weakest points of the system through which the oil could escape.

Reasons for failure:

- Overflow of liquid. No matter how trivial it may sound, oil can leak due to its overflow into the oil compartment. If you filled in lubricant “by eye” and did not check its level, a leak may form around the entire perimeter of the engine. The excess amount of material circulating under high pressure in the internal combustion engine will simply be squeezed out of the working space and flow down the outer sides of the internal combustion engine. The problem can be easily fixed: unscrew the oil plug at the bottom of the engine and allow excess fluid to drain out of the crankcase.

- Wear, incorrect installation or destruction of sealing elements. If the car has been sitting for a long time, the seals and gaskets may have failed due to insufficient moisture. After starting the car, they cannot function normally (their ability to be elastic is lost), and therefore lubricant leaks out. The solution in this case is to replace the problematic parts with new ones; You can read on the Internet how to correctly install sealing parts to eliminate oil leaks in the engine.

- Insufficient crankcase ventilation. Excessive accumulation of exhaust gases in the car crankcase can create additional pressure and squeeze consumables out. This situation occurs when the ventilation system ducts are clogged. An oil deflector valve will help diagnose this problem. Check its condition. Did you see a bluish or dark brown coating? This means that the reason for the leaks lies precisely here. If the presence of deposits still raises doubts about insufficient crankcase ventilation, cover the open oil filler neck with a small sheet of white cardboard and start the car engine (it is recommended to keep it at 900-1100 rpm). A tight fit of the cardboard to the oil fill hole indicates normal operation of the ventilation system. Otherwise, it is necessary to clean or replace the engine pipes.

- Valve cover deformation. In rare cases, when car manufacturers use low-quality metal, a violation of the geometry of the valve cover may occur, which will be accompanied by large oil losses. Unfortunately, installing a new gasket will not solve the problem. The only possible option is to replace this very cover.

“Escape” of transmission oil

If the oil between the engine and gearbox has an unpleasant, pungent odor, it means it is leaking from the vehicle’s transmission system. Moreover, a similar problem occurs most often on automatic transmissions: in a manual transmission, the oil level is much lower than the input shaft bearing.

The most likely cause of lubricant leaks from an automatic transmission is most often a malfunction of the torque converter and oil pump. And it is not possible to repair these units on your own: dismantling the elements is extremely labor-intensive. To restore the car to its former performance, a complete replacement of the automatic transmission or its expensive repair will be required.

The most “harmless” gearbox ailment for a car enthusiast can be banal wear of the seals. By changing them, you can continue to operate the car as usual. Incorrect installation of the dipstick (if equipped) can also cause loss of lubricant.

If you notice that one of the two systems of the car is leaking, but you could not recognize where exactly the oil is coming from, then specialists from service centers will help you deal with problems in the engine or gearbox. The main thing is not to put off the decision until later. Oil starvation can lead to complete loss of vehicle performance.

Measures to prevent oil leaks

It is impossible to completely protect your car from problems, but you can significantly reduce the likelihood of their occurrence. To do this, just follow a few simple rules:

- Constantly check the lubricant level with a special dipstick. Make it a habit to monitor the amount of engine oil every 5-6 days. This measure will allow you to recognize the presence of a problem before it becomes critical. Yes, all modern cars have a special sensor that informs the driver in case of oil leakage from the engine. But it is activated only when more than 300-500 ml is consumed.

- Maintain your vehicle regularly. This way you can promptly notice a damaged system element and replace it with a new one. In addition, regularly changing the oil fluid will prevent the formation of soot and sludge deposits, and increase the degree of protection of motor elements from excessive wear.

- Buy only products recommended by your vehicle manufacturer. Your vehicle's owner's manual contains information about the recommended engine oil viscosity. Compliance with these requirements will allow you to extend the life of the propulsion system. When choosing an oil liquid, pay attention to the design of the product and the quality of its container so as not to run into a fake. As for choosing a brand, you should rely on intuition. Many companies have a good reputation in the world market, but it is impossible to say unequivocally which oil is better - after all, each vehicle has its own requirements for fuels and lubricants.

- Do not load the engine if it has not been properly warmed up. Did you start the car in the cold and immediately decide to drive it? Then stock up on plenty of motor oil for regular top-ups. Thickened liquid circulates unevenly in a cold system, so pressing the gas pedal can cause it to be squeezed out of the system; To prevent oil from squeezing out, it is recommended to warm up the engine for 10-15 minutes.

- Buy only original spare parts. If you find the reason why oil is leaking from the engine or gearbox, immediately begin repairing the car. But when choosing new parts for the system, try to give preference to original spare parts. Their quality (as well as price) is much higher than that of their “Chinese” counterparts, which means they can last your engine longer. By the way, non-original spare parts may differ in size from the original ones, which in turn will affect the tightness of the structure.

- If it is not possible to carry out maintenance of the vehicle yourself, entrust the work to professionals. And not to “garage technicians,” but to service centers specializing in servicing vehicles.

What should you keep in mind?

Undesirable consequences can be caused by mixing fluids of different manufacturers and viscosity characteristics: if the oil leaks while driving, and there is nothing to top it up with, the car cannot be operated further. Call a tow truck and take the car to the nearest service station. Adding oil of a different composition - transmission or engine - is not allowed due to the fact that a destructive chemical reaction may begin inside the installation, which in turn will lead to even greater consequences. Of course, if a loss of fluid occurs on the highway, the driver can fill the system with oil at hand, but only to get to the specialists. In the future, the oil “compote” will have to be drained, and the installation into which it was poured will have to be thoroughly rinsed.

The lubricating fluid used for the engine and transmission is the component that ensures the performance of the vehicle. One of the problems that a car owner often faces is an oil leak between the power plant and the gearbox. It does not matter what fuel the vehicles run on. This malfunction should be corrected immediately, as it is a sign of a serious breakdown.

Use of engine and transmission oils

Mineral, synthetic or semi-synthetic fluid can be used for the engine and transmission. The synthetic version of the fuel is popular. It makes it easier to start the power unit. At low temperatures this oil:

- does not thicken;

- Optimal fluidity is maintained.

Mobil 1 transmission fluid

Mobil 1 oil has these qualities. Even at -40°C it does not lose its properties.

On most cars, the engine oil is changed at 10,000 km, and the transmission fluid must be replaced at 50,000 or 60,000 km.

Thus, engine and transmission fluids differ in their performance properties. The car system needs to be checked if there are leaks between the engine and gearbox. Adding, for example, synthetic oil to mineral oil leads to leaks. In this case, you should replace the filled oil and add what was previously there.

Causes of oil leakage between the gearbox and engine in a car

There are seals in the engine compartment. The main function of the oil seal is to prevent leaks and fuel on the moving elements of the power plant, as well as the gearbox. To replace this consumable item, it is necessary to drain the fuel and remove all fasteners. Armed with a screwdriver, the oil seal is dismantled.

Every 10,000 km, the car must be sent for diagnostics, where workers can check the condition of the breather. If this element becomes clogged, oil leaks from the gearbox or engine due to the fact that the necessary ventilation is not provided. The consequence of this is an increase in pressure in the automotive system. This leads to the oil seals being squeezed out of their normal place, as a result of which the driver is faced with a problem such as oil leakage.

If there is an oil leak on an automatic transmission, you must:

- check the operating capacity of the torque converter;

- condition of the oil pump.

Ignoring this malfunction will lead to large financial costs. In some cases, installing a new gearbox will cost less than repairing an automatic transmission.

Another reason why oil leaked from the box is an incorrectly installed dipstick. This item allows you to accurately determine the oil level. If it does not close the channel well, there is a risk that a leak will occur.

Thus, there are several reasons why oil leaks from the gearbox. Firstly, this is the wear of oil seals and sealing elements. This is often a consequence of their natural wear and tear. The low quality oil used also leads to wear of the seals. In this case, the consumable must be replaced. Secondly, loose fastenings and bolts. They need to be adjusted. You also need to check the breather. All of these are common causes that are easy to fix on your own. In this case, you need to determine the area of the leak. You can find smudges under the car.

Oil leak locations and troubleshooting

If oil leaks from the gearbox, the vehicle will malfunction. To get rid of the reasons why there is an oil leak between the engine and the gearbox, it is advisable to drive the vehicle into an inspection hole. Thanks to this, it is possible to accurately determine the place where the fuel is leaking.

It should be noted that the detection of oily drops under the car is not only a consequence of the fact that the gearbox is leaking, but also the result of the fact that the steering rack is broken.

It is possible to eliminate the reason why oil drips between the engine and gearbox by replacing the gearbox. A manual transmission is distinguished by its maintainability; not every service center undertakes to repair automatic transmissions.

How to fix an oil leak? In order to prevent the occurrence of drips, it is advisable to ensure the tightness of lubricant complexes. Thanks to this, the transmission system will operate at high pressure. On a number of car versions, in order to replace the oil seals, the box must be removed from its original location. This process requires care. That is why it should be entrusted to specialized service workers.

When there is an oil leak from the gearbox, a grinding noise may occur at the same time. The cause of the grinding noise is often a lack of fuel filling. The lower the oil level, the higher the risk that the components of the speed box will fail prematurely. In addition to this, a low engine oil level will cause the engine to overheat, which can lead to premature cylinder head failure.

The amount of oil for the automotive system must comply with the standards established by the car manufacturer. If there is an excess amount of liquid, it is squeezed out through the sealing elements. It is advisable to replace the gearbox sealing elements if they cannot withstand the oil pressure.

An oil leak from the gearbox is a consequence of the driver having an aggressive driving style. If oil is leaking between the engine and gearbox, then this problem should not be postponed. Fixing the problem early helps minimize the risk of serious problems with your car.

Thus, one of the common breakdowns on a vehicle is oil leakage between the high-speed gearbox and the power unit. Timely car care will prevent the occurrence of leaks from the gearbox. For each version of the car, you should use oil of appropriate quality. Defective consumables that cause leakage must be replaced.

Every driver who takes care of his car eventually develops a useful habit: before setting off on a trip, it is necessary to check for any signs of oil or antifreeze leakage under the car. A good solution would be the following method - in the evening, before parking the car, place clean cardboard (for example, from a box) under the engine and gearbox, and then in the morning you will be able to more accurately localize the problem.

If you see something suspicious, then try to find the cause of the oil leak between the gearbox and the engine and fix it - at a specialized service station or yourself. One common place for oil leaks is the connection between the transmission and engine. Well, if you keep the engine compartment clean, then it will be easier to find the cause of the loss of lubricant. Otherwise, before diagnosing, you will have to wash everything clean in order to accurately localize the leak.

Features of the engine and gearbox lubrication system

The engine and gearbox are lubricated with oils of different chemical compositions. An experienced driver or mechanic will be able to immediately determine, by smell or color, which unit is losing lubricant. The engine is equipped with a forced oil supply system to the rubbing components and assemblies.

In a manual gearbox, oil is supplied to friction points by “splashing” from the rotating parts. In automatic transmissions, the supply occurs using an oil pump. It is rare for a manual transmission to leak oil when the car is stationary. The design feature is such that the oil level is less than the bearing on the input shaft. Therefore, on this type of box, losses occur during movement.

The oil change intervals for these units are different: engine oil is changed every 8-15 thousand kilometers, and transmission oil is replaced every 50-70 thousand.

The amount of oil poured into the engine or transmission must comply with the manufacturer's standards. With oil starvation, rubbing parts wear out faster and their service life is significantly reduced.

If the oil is poured in excess, then it is possible that the excess may simply be squeezed out through weak spots. It is necessary to constantly monitor the level of lubricating fluids. Make it a habit - before starting the car, check the oil level in the engine, gearbox, coolant expansion tank, and the amount of brake fluid. Timely treatment will be much cheaper than serious repairs.

Possible causes of oil leakage between the gearbox and engine

As soon as you notice the first signs of an oil leak, you must immediately look for the location of the breakdown. We cannot delay solving this problem. You don’t want to end up somewhere in the middle of a field and return home in a tow truck, do you? The most convenient way to determine the location of the oil leak between the gearbox and the engine is on a lift or pit. Drops of liquid are definitely a flaw and need to be gotten rid of.

As soon as you notice the first signs of an oil leak, you must immediately look for the location of the breakdown. We cannot delay solving this problem. You don’t want to end up somewhere in the middle of a field and return home in a tow truck, do you? The most convenient way to determine the location of the oil leak between the gearbox and the engine is on a lift or pit. Drops of liquid are definitely a flaw and need to be gotten rid of.

It is unlikely that it will be possible to instantly identify a broken unit - the lack of direct access to vulnerable components makes this difficult task difficult. Most often, the problem is in the gearbox and, most likely, you will have to dismantle it to accurately diagnose and fix the problem.

Each car has its own characteristics, but there are some general principles for diagnosing and repairing breakdowns. First of all, you need to decide what type of oil is leaking - oil from the engine or from the gearbox? This can be determined by the smell and type of contamination. The size of the stain can determine the severity of the problem and the amount of oil lost.

In used cars, the main oil seal of the engine first begins to leak. Increased axial movement of the crankshaft causes the oil seal to be squeezed out and leakage occurs. Worn oil-resistant rubber of the oil seal can no longer hold back the oil, which has warmed up to a fluid state. When the crankcase ventilation system is clogged, the pressure in the system increases and excess oil escapes through weak points.

The transmission also has its own ventilation system: through a special breather, expanded hot air leaves the system. If it is clogged, excess pressure is created and the oil is also squeezed out. There is only one realistic option for eliminating oil seal leaks - replacement. And if you change one of the seals, it is better to immediately replace the second one, so as not to remove the box twice. You should immediately check the shaft play, the condition of its seat, and bearing wear.

Causes of oil leakage that can be eliminated without removing the box:

- the drain nut is loose;

- loose installation of the measuring probe (if it is provided in the transmission design);

- Sensors are poorly wrapped.

If you can’t get away with it and the oil leak between the gearbox and the engine continues, get ready for more serious and expensive repairs. By the way, check with the mechanic - maybe replacing the box will be cheaper than seriously repairing it.

Reasons requiring removal of the box from the car:

- violation of the tightness of gaskets or seals;

- wear of the main oil seal;

- wear of the gearbox input shaft oil seal;

- incorrect installation of seals;

- violation of the pallet geometry - a struck or bent pallet tears the gasket;

- a clogged crankcase ventilation system can create excess pressure and squeeze out oil;

- wear of the shafts that connect the engine and gearbox;

- gearbox input shaft play;

- breakdown of the torque converter or oil supply pump on automatic transmissions.

Oil additives

Some drivers, when they see an oil leak between the gearbox and the engine, immediately go to the auto chemical store to get some magic oil. Additives contain special substances that restore the elasticity of seals. This property ensures the restoration of tight contact between the oil seal and the shafts and can temporarily eliminate oil leaks. Yes, the additive can help, but only for a while and only if there is a slight leak in the system.

Some drivers, when they see an oil leak between the gearbox and the engine, immediately go to the auto chemical store to get some magic oil. Additives contain special substances that restore the elasticity of seals. This property ensures the restoration of tight contact between the oil seal and the shafts and can temporarily eliminate oil leaks. Yes, the additive can help, but only for a while and only if there is a slight leak in the system.

The wear and tear of the part will not go away, and therefore the breakdown remains, and the chance of having to undergo more expensive repairs or replacement of the unit increases significantly. The use of oil thickeners is not recommended. They can eliminate the leak, but at the same time they will worsen the lubrication of the components, which is fraught with increased wear of the motor or gearbox. If you decide to use an additive, choose a softening sealant.

Let's summarize:

- traces of oil on the garage floor are a mandatory reason to inspect the engine, gearbox and connection points;

- the weak point of used cars is the oil seals; most likely, their service life has come to an end;

- You should definitely check the engine and gearbox ventilation system;

- the additive will not help - most likely, you will have to treat your car more seriously.

Lubricating fluid is one of the main components that ensures the performance of a car, so its level and condition must be closely monitored. Having discovered signs of oil leakage from the engine or gearbox, you must immediately identify and eliminate the cause that caused the problem. This will allow you to avoid serious troubles associated with the failure of the power unit directly during the trip and will postpone the period of forced expensive repairs for a long time.

Signs of an oil leak

Oil leakage from a car’s power unit is a common phenomenon that is well known to many drivers. The engine design itself contributes to the occurrence of this problem - it uses many sealing elements (gaskets or seals), through which lubricant flows. Signs of a fluid leak, in addition to a decrease in its level, which can be determined using a dipstick, appear in the form of oily drops, streaks and stains on parts or under the bottom of the car. Problems in the lubrication system are also indicated by the appearance of gray (blue) smoke from the exhaust pipe or from under the hood of the car.

Photo examples

The engine becomes covered with a black oil coating

The engine becomes covered with a black oil coating  Drops of oil appear at the bottom of the engine

Drops of oil appear at the bottom of the engine  Gearbox parts become covered with oil stains

Gearbox parts become covered with oil stains  Oil stains appear on the engine housing

Oil stains appear on the engine housing  The lower part of the engine becomes oily

The lower part of the engine becomes oily  A leak is indicated by oil stains under the bottom of the car.

A leak is indicated by oil stains under the bottom of the car.

Where is the grease leaking, dripping or leaking from?

This question is asked by every car enthusiast who discovers an oil stain under the bottom of his car. The first thing that comes to mind is problems with pads or cuffs, but which ones exactly? The fact is that oil can leak from the engine itself or from the gearbox, where the input shaft oil seal (manual transmission) or fluid coupling (automatic transmission) is located. How is the source of a leak determined? Experienced craftsmen can distinguish transmission oil by its smell, but for everyone else, we recommend a simpler method: place a particle of leaked lubricant in a vessel with ordinary water - the engine oil will go to the bottom in the form of a drop, and the transmission oil will “scatter” across the surface.

Attention! Only by determining where exactly the oil is leaking from can you take further action to solve this problem.

Causes of malfunctions and ways to eliminate them

An oil leak that goes undetected in time can lead to serious damage to the power unit. To eliminate the problem and prevent further leaks, it is important to know the causes of their occurrence. So, the malfunction may be caused by:

- Insufficient ventilation of the unit crankcase. The problem is typical for heavily worn engines and gearboxes. The ventilation ducts of such units are very dirty - this creates increased pressure in the crankcase and leads to the displacement of lubricant through oil seals, cuffs or gaskets; oil can drip quite copiously.

- Excessive amount of lubricant poured into the unit. An excessive amount of oil contributes to an increase in oil pressure in the system. In this case, the seals and gaskets cannot withstand the increased operating pressure and “break through” (begin to leak).

- Incorrect choice of lubricant. Long service life of oil seals and gaskets is ensured by the type of lubricant recommended by the vehicle manufacturer. The use of another, even higher quality oil leads to the destruction of the sealing elements.

- Long-term (more than a month) vehicle downtime. Gaskets and seals can fail if the engine does not warm up for more than four weeks - all the oil drains into the crankcase, and the seals that remain without lubrication dry out and collapse.

In addition, lubricant leakage occurs due to defects:

- oil pan;

- intake manifold;

- oil filter;

- distributor;

- oil pressure sensor.

Attention! If the low oil pressure indicator located on the dashboard is activated, the vehicle is prohibited from operating.

Let's take a closer look at those components and assemblies of the car, the malfunction of which can cause an oil leak.

Engine

Lubricant leaks are a serious challenge for anyone, especially a novice driver. Note that it is quite difficult to independently eliminate the causes of blue smoke from the muffler. It is no less difficult to eliminate oil leakage due to severe wear of the shaft or piston-cylinder group of the engine - with such problems it is better to immediately contact a service station, where experienced craftsmen will quickly and efficiently repair the engine. Today we will only talk about those defects that you can eliminate with your own hands.

Crankcase ventilation system

Modern car engines are equipped with “dual” crankcase ventilation: the first part of the system operates at high crankshaft speeds, the second - at idle. This equipment includes:

- An oil deflector valve that prevents oil vapor from penetrating into the engine combustion chamber. If the device becomes clogged with carbon deposits, its normal operation will be disrupted - oil will penetrate into the air filter and then into the intake manifold. The car engine will begin to smoke heavily.

- A ventilation valve that regulates the pressure of gases that enter the manifold. In idle mode, the device is in the open state, closing smoothly with increasing speed. Incorrect operation of the part leads to a lean mixture, causing interruptions in the engine.

- Dense rubber tubes that remove excess gases that enter the crankcase. These elements are ventilation channels; becoming clogged with slag and fumes, they disrupt the normal operation of the system. Exhaust gases create excess pressure, which leads to the fact that most sealing gaskets, unable to withstand such loads, are destroyed and begin to leak the steam-oil mixture.

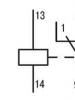

If ventilation channels 2 and 3 are contaminated, there may be an increase in pressure in the system and breakdown of sealing gaskets

The crankcase ventilation should be checked first, paying special attention to the condition of the oil deflector valve installed in the valve cover. You can verify that the system is working as follows:

- Remove the oil filler cap.

- Cover the neck with a piece of thick cardboard.

- Start the car engine.

- Increase the crankshaft speed to 1000 rpm.

Attention! The ventilation system works normally if the cardboard is pressed tightly against the neck due to the vacuum that forms in the engine crankcase. Otherwise, all rubber tubes included in the assembly should be cleaned of internal carbon deposits or replaced with new ones.

If oil leaks from under the valve cover, remove it and thoroughly clean it of internal carbon or deposits.

Oil leaks from under the valve cover are eliminated by removing deposits

In addition you will need:

- Wash the oil separating valve of the crankcase ventilation system and the mesh located in it.

- Replace the rubber sealing gasket, having previously lubricated it with sealant on both sides.

- Apply sealant to the rubber washers that are installed under the bolts securing the cover.

- Reinstall the valve cover and tighten the mounting bolts.

Diagram of drawing fastening bolts

Attention! When tightening the mounting bolts, be careful - excessive force may damage the surface of the cover or strip the threads.

If you find that fluid is leaking from under the oil filter, the part should be tightened. Typically, an oil leak in this place can only occur when installing a defective device, so the correct solution would be to completely replace it.

An oil leak from under the filter housing can only be eliminated by replacing it.

Attention! A filter of a collapsible design should be changed at the first sign of a malfunction - in most cases, even a minor leak can lead to complete destruction of the part body.

Pressure meter

A leak from under the oil pressure sensor can be eliminated in the only way - by immediately replacing the device. The urgent need to perform these actions is due to the fact that the cause of the malfunction here is wear and disruption of the integrity of the rubber diaphragm located inside the part. The element can break through at any time - then the oil pump through the sensor will expel all the lubricant from the engine in a few minutes.

The problem of oil leakage from under the pressure sensor can be solved by urgently replacing the device

Attention! Most oil pressure sensors produced by the same manufacturer differ only in the connector design and can be interchanged.

Distributor

Fixing a leak that occurs from under the distributor cap is not difficult. To do this you need to do the following:

Attention! The distributor must be installed so that the slider takes the same position as before the dismantling procedure.

Pallet

Oil flows out of the engine crankcase only after the pan hits uneven road surfaces.

Leaking engine oil pan needs to be straightened

In case of critical damage, the part must be replaced, but if the pallet is simply “stretched” on the mounting bolts, then it can be straightened (straightened). To do this you will need:

- Drain the engine oil.

- Unscrew the fastening bolts and disconnect the part from the crankcase.

- Thoroughly clean and rinse the tray of all kinds of deposits and dirt.

- Straighten (straighten) the surface.

- Apply sealant along the contour of the part and install it in place, tightening the fastening bolts.

Attention! When installing the pallet, tighten the bolts evenly and with extreme caution - you can easily strip the threads and break off one or more fastening elements.

Oil seals

Any modification of a car engine is equipped with two sealing gaskets - crankshaft oil seals, framing the mechanism at the front and rear. The exhaustion of the working life of parts or excess pressure of crankcase gases can cause oil to leak through these elements. Please note that this problem can only be resolved by replacing the seals.

Oil leakage through shaft seals

Depending on the design of the engine, the front “frontal” oil seal is mounted in the cylinder block cover or the oil pump housing. To replace it you will need:

To eliminate oil leakage through the rear “main” oil seal of the crankshaft, you will need to dismantle the cardan drive, disconnect the gearbox and clutch housing. The cage in which the sealing element is installed is removed as follows:

There are other seals in a car engine that can leak - gas camshaft seals or oil pump shaft seals. Replacing these elements is done in the same way: they are lubricated with lithol and installed with a spring inward.